Yeast

YEAST PROCESSING MACHINE

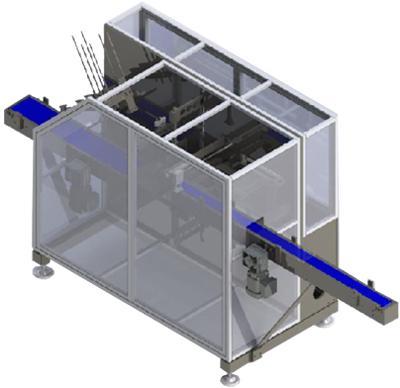

EXTRUDER AND CUTTING UNITS

EC 110 yeast processing machine is a fully automatic machine which is in a position to receive the yeast coming out of an upstream system, and mixes, extrudes and cuts the same into cubes, without interruption or the operator’s intervention. At optimal speed, the machine is able to maintain a maximum work cycle of 110 pieces per minute (depending on product). It is composed by: an extruder and a cutting sections.

Both sections of the machine are made entirely of stainless steel, in compliance with mandatory standards for food processing machines (EN 1672-2); in particular the machine is designed to avoid any storage of processing waste in all areas in direct contact with food. Special attention during the development of the project, has been given to the machinery cleaning procedures.

Cutting unit

The cutting unit is equipped with a Teflon surface, which receives the yeast drawn from the cone extrusion, and supports it up to the tunnel of the vertical cutting area.

An encoder fitted to a roller detects the length of the drawn piece coming into the tunnel,

to determine the cutting dimensions.

Mixing unit

An outer system, located upstream of the machine, conveys the yeast (already in the shape of dough) into the unit hopper. Inside the hopper, the yeast is mixed by two rotating shafts.Yeast, compressed and well mixed, comes out from the extrusion cone by means of am auger screw, in the form of a continuous drawn piece with a rectangular section; it is possible to use reduction gears of two different sizes at the extrusion area output.

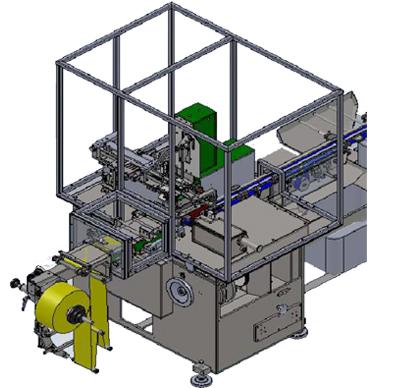

YEAST TRAY MACHINE

TMA 10 is a totally pneumatic machine which is able to package a bundle of product of

a uniform prism shape. Its production rate is max 10 carton/minute.

The machine operation has five stages:

- Product in feed

- Bundle transfer

- Box erection

- Exit tray

- Lid closure

Special attention during the development of the project, has been given to the machinery cleaning procedures.

The signal lamps and the Siemens touch screen are washable.

The photocells of this machine are positioned on the conveyor belt to check the stacking and the minimum load.

The bundle is transferred on the box erection station. The trays are erected from a flat blank and once they are filled with the product, they come out in one row.

The machine works with a motor served by inverter.

The tray will be pasted in three points with the glue. The machine has an air pressure system for the pneumatics movements.

YEAST WRAPPING MACHINE

The machine is equipped with one head that actives one wrap cycle. Some small

components are made in Teflon.

The wrapping product is automatically sealed. The machine works with a motor served by inverter, controlled by sensors installed at the in-feed belt.

The machine is entirely made of stainless steel,in compliance with mandatory standards for food processing machines (EN 1672-2); in particular the machine is designed to avoid any storage of processing waste in all areas in direct contact with food. Special attention during the development of the project, has been given to the machinery cleaning procedures.

The upper sensors adjust the speed of the machine during the production.

It is possible to totally control the machine with the touch screen. In case of lack of cubes, the machine stops.

It has a system of control that informs the technicians when the paper is finished.

The machine even has an electronic speed control. Its motor classification is IP 55. The control of the machine with PLC touch

screen is incorporated, it rotates on itself. CPU upgrade:from Siemens 1200 to model 1513 TF(axis control).

The signal lamps and the Siemens touch screen are washable.