Process

In the biological production of vinegar, acetic acid is derived from ethanol using acetic acid bacteria (Acetobacter). To produce vinegar in liquid form, oxygen has to be distributed to the bacterial cell. In modern vinegar production units aerators (turbines) are used to introduce fine air bubbles into a fermentation tank to allow the strictly aerobic bacteria to survive in a submerged culture.

Besides traditional methods, today there are two major processes used in vinegar production technology:

· Semi-batch process for vinegar production with up to 15% acidity

· Fed-batch process for vinegar production with more than 20% acidity

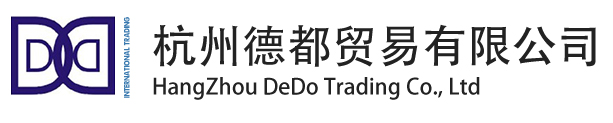

Semi-batch (up to 15% acidity)

The Semi-Batch-Process for the production of wine / cider / fruit / alcohol vinegar is a fermentation process at which 1/3 of the fermentation liquid is discharged when reaching a residual alcohol content of ~0,3% and replaced by charging fresh mash.

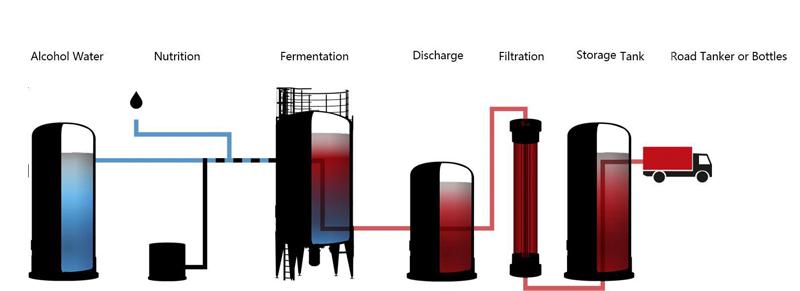

Fed-batch (more than 20% acidity)

The Fed-Batch-Process for the production of alcohol vinegar is a fermentation process at which 2/3 of the fermentation liquid is discharged when reaching a residual alcohol content of ~0,3%. Afterwards the discharged volume is replaced by slowly recharging the respective raw materials. In contrast to the semi-batch process, during the ongoing batch, alcohol and nutrients are apportioned in a certain quantity so that the total concentration increases slowly up to >20%.