Systems for Pork

VPS 2000

Grading of Pork Primal

Quality Assurance

Payment Depending on Real Value

Application and issues

In order to guarantee optimum sales of cuts of meat and meat products it is essential for packers to buy the right sides of pork at the right quality and price. The need is to know the real value of the side regarding both the supplier's price and the sales of the processed material.

The quality of pork your business needs is not described by the simple equation

good value = high lean meat percentage of side

as it is often told. It depends on many more features:

· lean meat percentage of side

· lean meat percentage of all other cuts, especially belly

· yield on saleable meat

· colour of meat: PSE/ DFD

and others that are most of chemical or biological nature.

The idea is to measure automatically all the above mentioned parameters that will give you a much better understanding of the material flowing through the cutting lines. Using this data enables you to:

· compare ordered to delivered quality on an objective base

· feed-back the results to the suppliers

· choose the best suppliers for your needs

· decide how to use different cuts for best business value.

Starting with this demands from the industry it was our issue to build a system that reliably measures the quality and value of pork cuts - a tool to increase your business value.

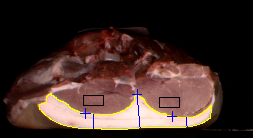

A sample picture: this picture is all VPS 2000 needs to calculate

all data of the side from the shoulder cut.

A sample picture: this picture is all VPS 2000 needs to calculate

all data of hams.

What does VPS 2000?

VPS 2000 is a VIA system (Video Image Analysis) which meets exactly the requirements as mentioned before. It is used in the cutting line for the evaluation and sorting of the quality of cuts of pork.

The new technology allows an objective, constant and value-optimised sorting of the cuts of meat. VPS 2000 supplies the following information:

¨ lean meat percentage of the cut side

¨ lean meat percentage of the ham

¨ lean meat percentage of the belly

¨ colour of loin

¨ PSE and DFD recognition

¨ combined with scales: yield valuation

Which advantage offers VPS 2000 to the customer?

The objective quality information for each cut of meat is of multiple advantage to each slaughter and meat cutting plant:

¨ exact incoming inspection for each side

¨ quality assurance

¨ payment of suppliers due to measured and documented data

¨ sale of bellies according to the real value

¨ sale of ham according to the real value

¨ exact knowledge of ’What’s in stock’

¨ direct transparency for the management

The VPS 2000 has proved successful in practice. The availability of the system is almost 100%. This reliability is not surpassed by any other measurement system working on-line in the cutting lines.

Since the needs of the cutting plants are not identical, VPS 2000 was designed in such a way that it can be adapted to any customer requirement. The customer can define freely the measurement and sorting criteria. These will be programmed by our service staff upon system installation.

System environment for VPS 2000

In commercial cutting plants, standardised cuts are performed mostly by means of semiautomatic control systems. Typically, a cut is made in the area of the 6th/7th or 4th/5th dorsal vertebra. VPS 2000 accepts also cuts at other points.

It is important that the cut is made with a circular knife. A saw is unusable in this case. VPS 2000 „looks“ at the cut of the middle piece from the side of the shoulder. A sample picture is shown on page 3. In order to guarantee a video image analysis, a clear cut must be made without glazing or smearing of the cut surface. Such glazing or smearing as caused by sawing lead inevitably to wrong measurements.

Suitable parting knifes are available from many manufacturers. On request, we supply a list of manufacturers. However, a parting saw must in all cases be replaced by a circular knife.

From the aforementioned information it can be concluded furthermore that the view onto the first cut of the middle piece from the side of the shoulder must be free and unobstructed. After the parting of the shoulder, it must be taken away (upwards, downwards or by a faster or slower running conveyor belt). The middle piece is then transported on a conveyor belt through a channel in the VPS 2000. The dimensions of the channel and the maximum possible size can be seen in the drawing the chapter ‘Technical Specifications’.

From this drawing, the space requirement for the VPS 2000 can also be seen. VPS 2000 can be installed on supporting pillars on the hall floor or suspended from the ceiling.

How does VPS 2000 operate?

As described before, the belly cut runs on the conveyor belt through the channel of the VPS 2000. A camera looks at the cut surface from the side of the shoulder. The image is taken automatically without the need of any stopping of the conveyor. An installed monitor shows the cut surface. By mean of a colour analysis of the stored picture, the fat, the lean meat and bones are identified. With these values and the knowledge of the anatomical structure of the swine we calculate the interesting features. All results are displayed on the screen after about 1 second. This information can be used in the further process, for instance for the control of a sorting unit or the labeling of the belly cuts according to a classification given by the customer based on the determined measurement values. The evaluation of the cut surface is used to derive all relevant data of side and all cuts of meat.

The data sets are stored a can be analysed afterwards off-line too. That is the usual way to look for supplier's quality, mean values and print reports.

Accuracy of estimation and comparison of competing systems

The tissue parts of the carcass, the ham and the belly are determined by estimation formulas which were developed and validated together with the Federal Institute for Meat Research. The accuracy of the estimation formulas is not surpassed even by considerably more expensive procedures.