Industrial Fermenter

Fermenters for industrial vinegar production

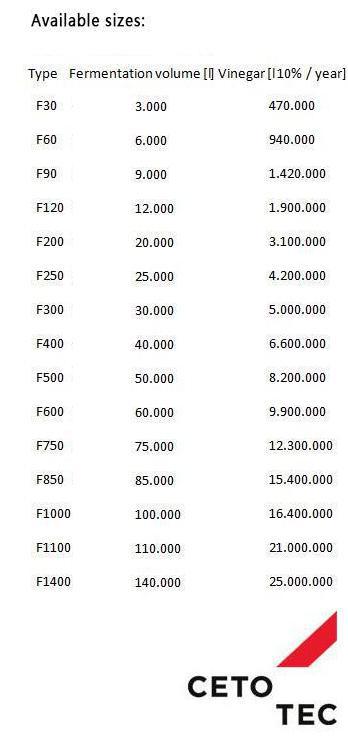

We deliver turn-key industrial scale fermentation plants with production capacities of up to 140m³. The fermenter is the core component of every vinegar production. It is delivered in high quality stainless steel and equipped with a custom-tailored cooling coil.

Description:

High performance aeration systems guarantee a homogenous and uninterrupted supply of oxygen to the fermenter, therefore optimally supporting the growth of the microroganisms. In our fermenters you can achieve up to 15% acidity when applying the semi-batch process as well as more than 20% acidity when applying the fed-batch process.

Function:

A complete fermentation

plant in vinegar production technology generally consists of the following main

components:

generally consists of the following main

components:

· High quality stainless steel tank with cooling coil

· Aeration system

· Foam system

· SIEMENS PLC – process control

· Acetoline – system for the on-line alcohol and acidity measurement / Alcocontrol – system for the on-line alcohol measurement

· Stainless steel pumps

· Sensors (filling level, temperature, alcohol volume)

Advantages:

· Technological leading engineering for the optimal construction of your vinegar fermenter

· High performance aerator design for vinegar production

· Easy to handle foam system with very low energy consumption

· Innovative alcohol and acidity measurement systems

· Reliable Siemens PLC control with well-proven software