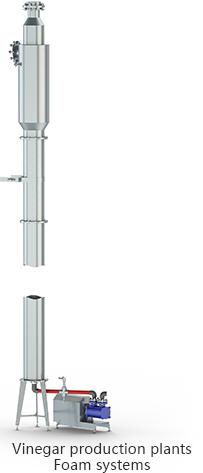

Defoaming System

Foam system for vinegar technology

Our foam system ensures thorough and at the same time energy-saving removal of foam as well as foam producing substances in your vinegar fermenter. This guarantees a higher and more stable fermentation performance while saving energy.

Description:

Foam producing substances are amongst others dead bacteria, their metabolites as well as unsoluable extracts from raw material. These substances are not only unwanted in the finished product but can also lead to lower fermentation performance as well as disruptions.Therefore the goal is to efficiently remove and in the long run minimize the amount of foam on the fermentation liquid. Due to its sophisticated design and ease in handling, our foam system is ideally suited for this specific task.Our foam system has been successfully installed in numerous vinegar fermenters / Acetators worldwide.

Function:

The foam is carried out by the exhaust air exiting the vinegar fermenter through a hole in the upper part of the outside fermenter wall. The foam flows into a foam collection basin with integrated foam separator and is subsequently pumped into a tank by the foam pump. High-value raw materials can be reintroduced into the fermentation process as foam concentrate.

The specially developed foam pump only needs 1,5kW and is started up only if a specific amount of foam concentrate has settled in the system. As every pump needs to be serviced after a couple of years, the convenient installation next to the fermenter enables user-friendly maintenance procedures.

Advantages:

-- Low energy consumption

-- Foam removal without any chemical additives

-- Reduction of new foam production by constantly removing foam from the fermentation

-- Reduction of fermentation disruptions by removing dead bacteria

-- User-friendly installation beside the fermenter